Focus on Repairing Isolated Problem Areas with APRIS

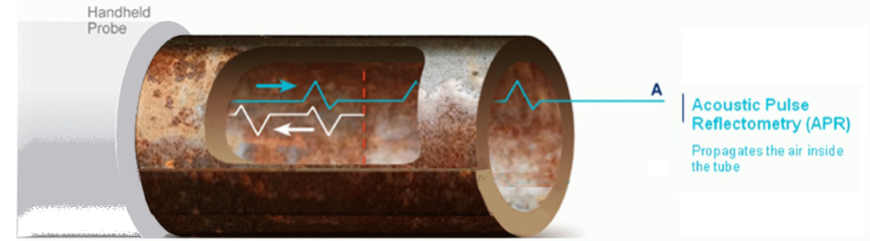

Why replace an entire air pre heater if most of the tubes are still in good working order? CMS uses an APRIS Acoustic Pulse Reflectometry non-destructive test to inspect each tube individually, technology that enables inspectors to identify not only the existence of tube failures, but also pinpoint their location. The APRIS works by sending an acoustic pulse down the entire length of a tube and back, showing flaws in real-time.

CMS inspectors analyze the data collected from each tube use it to create a detailed tube sheet map, which shows the location of tube holes and problem areas. This information in combined with findings generated by the company’s proprietary Air-Tight™ Air Leakage Calculator to create a comprehensive Executive Summary and a custom Financial Impact Report (FIR), including the tube sheet map, photos, and recommendations.

Demonstration of APRIS Testing Results

To demonstrate how APRIS establishes the location of the failure in the tube, we will follow a representative similar project effort. CMS performed APRIS testing on 15% of all tubes in the Heat Exchanger. The APRIS was recommended for use to identify the location of failures along the tube in order to further analyze the root cause of degradation in the air heater and assist in the development of future scopes of work.

For purposes of this discussion, we will focus on the section of the Heat Exchanger referred to as “Wide Pitch”.

Representative APRIS Inspection

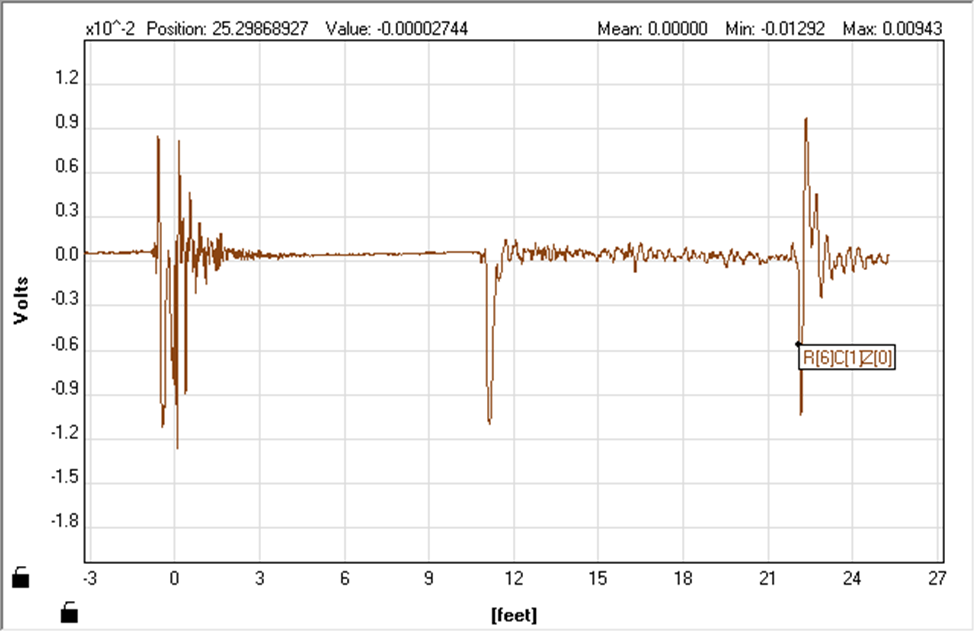

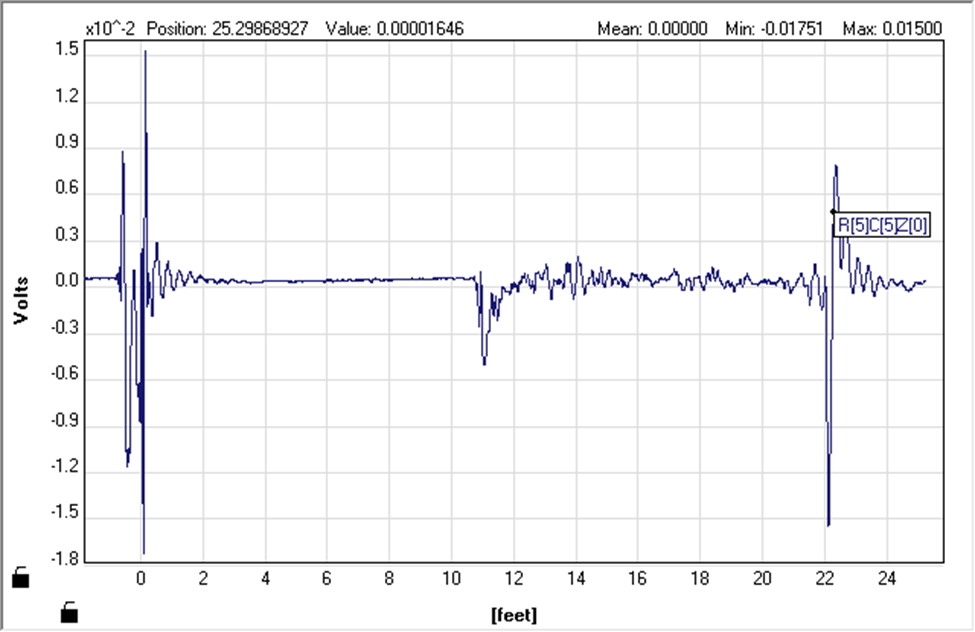

CMS performed NDT APRIS inspection on a total of 252 tubes in the wide pitch. Of the tubes tested, 50 tubes were found to have failed. The APRIS confirmed that failure is occurring at a localized pattern. Approximately 98% of failures are located at an average depth of 11’ from the top tubesheet. The average depth of 11’, puts the failures at the pass partition baffle separating the first and second combustion air passes.

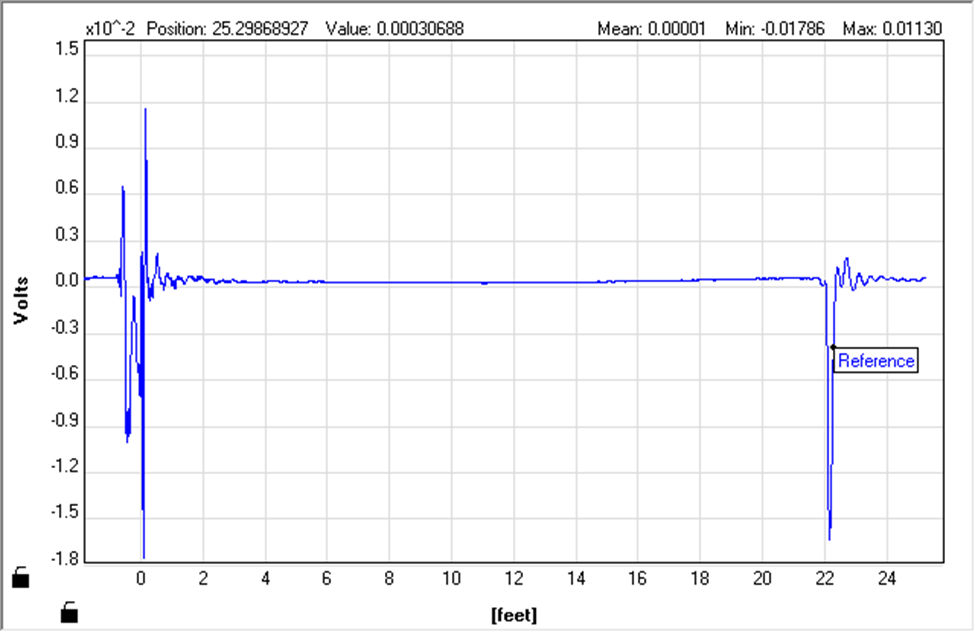

The following are examples of APRIS readings taken during this inspection. These readings are what the APRIS technicians are examining to determine what tubes have failed, and where along the length of the tube the failure has occurred.

Example 1

Example 2

Example 3

Conclusion

The use of APRIS Testing, based on the significant experience of CMS in using this technology, allows for the reliable and confident determination of location failures and results in prudent planning and budgeting for repairs, focused specifically on the tube locations requiring repair.

For further details or to request a system check-up, contact CMS.